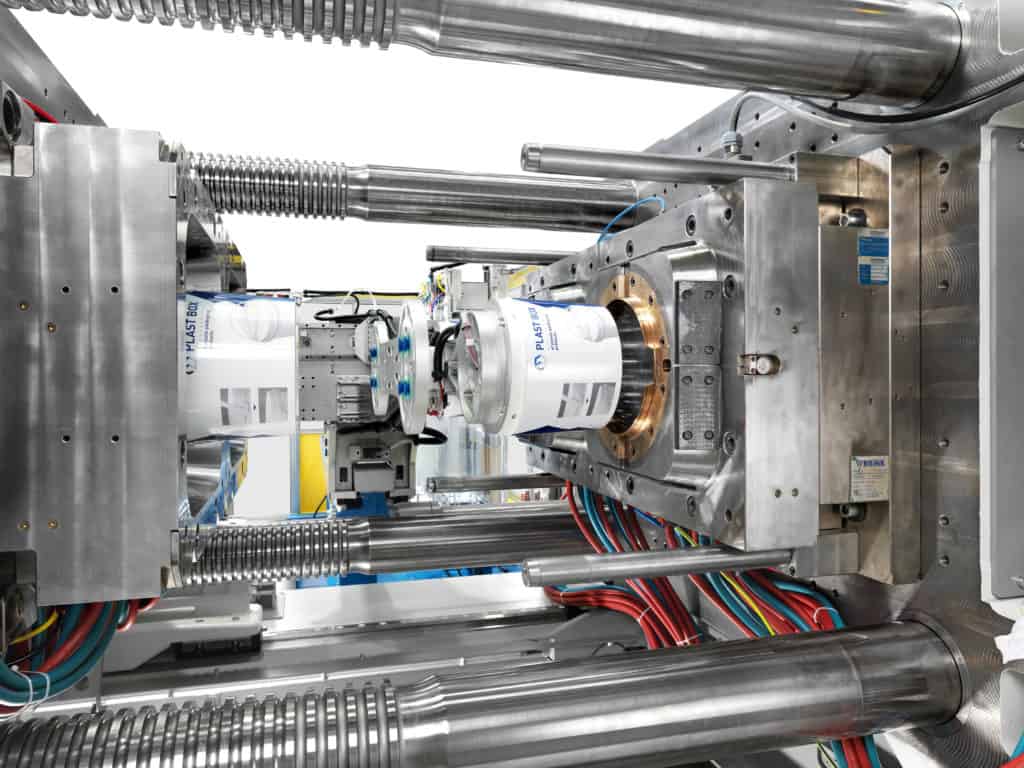

Streamline manufacturing line structures

Merritts understand that factory production line changes can be a major disruption. We will work with you to obtain a thorough understanding of your business and manufacturing process. This enables us to determine the most efficient method possible to carry out changes to your assembly lines.

On every machinery transport project we employ optimised planning techniques to ensure resources are continually maximised. We can also arrange for machinery removals to take place out of hours if necessary. This ensures production down time in minimised. Our project management team will attend all production meetings that are required to plan machinery installations to the smallest detail.

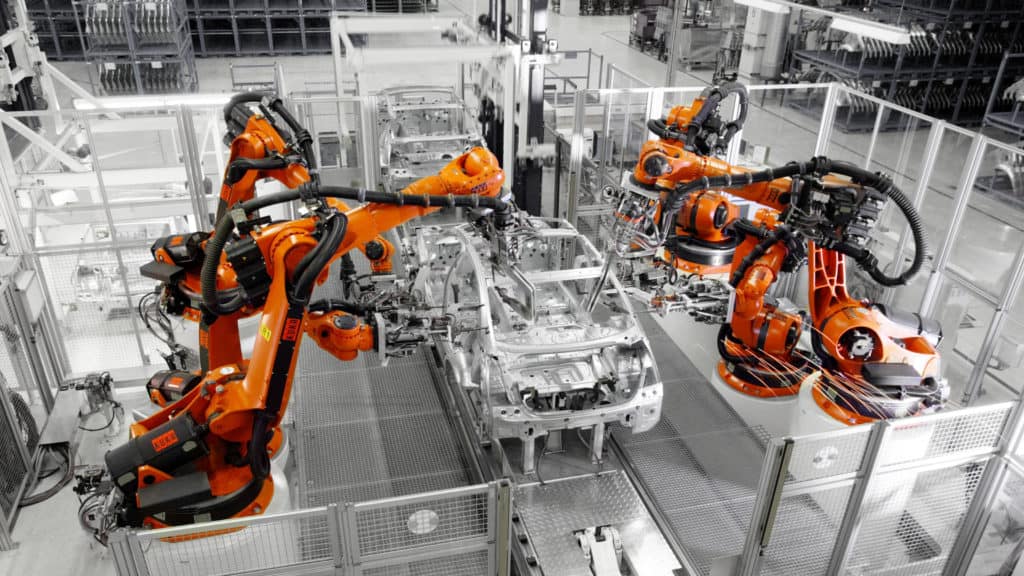

A fully qualified internal machinery moving team

Each of our internal machine move projects is assigned a dedicated project manager. They will also be supported by a fully trained engineering team which comprises: SSSTS trained foremen, riggers, HGV Class 1 & 2 drivers, crane operators and electrical & mechanical engineering specialists. Merritts also employ fully certified slinger signallers, and banksmen. Appointed persons are also part of the team to provide competent supervision when carrying out the moving and lifting of heavy machinery and equipment.

Our health and safety expertise

We’ll ensure all aspects of health and safety are covered, including the provision of detailed risk assessments, method statements, lift plans, training documentation and plant certification records. We plan everything to the finest detail to ensure your machine moving project is managed in a cost-effective and time-efficient manner.