Call FREE: 0800 046 9840

Email us: enquiries@merritts.uk.com

Changes in manufacturing demand often result in the need to relocate heavy machinery as part of a partial or complete factory relocation or closure. These circumstances often require a great deal of sensitivity as operations may need to be carried out confidentially under none disclosure agreements (NDAs).

Over 100 years of successfully completing factory relocation projects

As a result of over 100 years of experience, we understand the unique challenges that any production or assembly line changes, machine removals, or plant relocations required as part of a factory relocation project, can cause a major disruption to your manufacturing facility.

From disconnecting and dismantling plant in existing factories, to transporting them, reassembling and reconnecting them at a new site, our project management team will plan accordingly to ensure minimal production interruption during the relocation process.

We work closely with a customer base which ranges from local SMEs to global organisations in sectors such as aerospace, defence, automotive, food & drink, education, textiles, plastics, waste & recycling, metalwork, healthcare and pharmaceutical manufacturing.

What does Merritts factory relocation service look like?

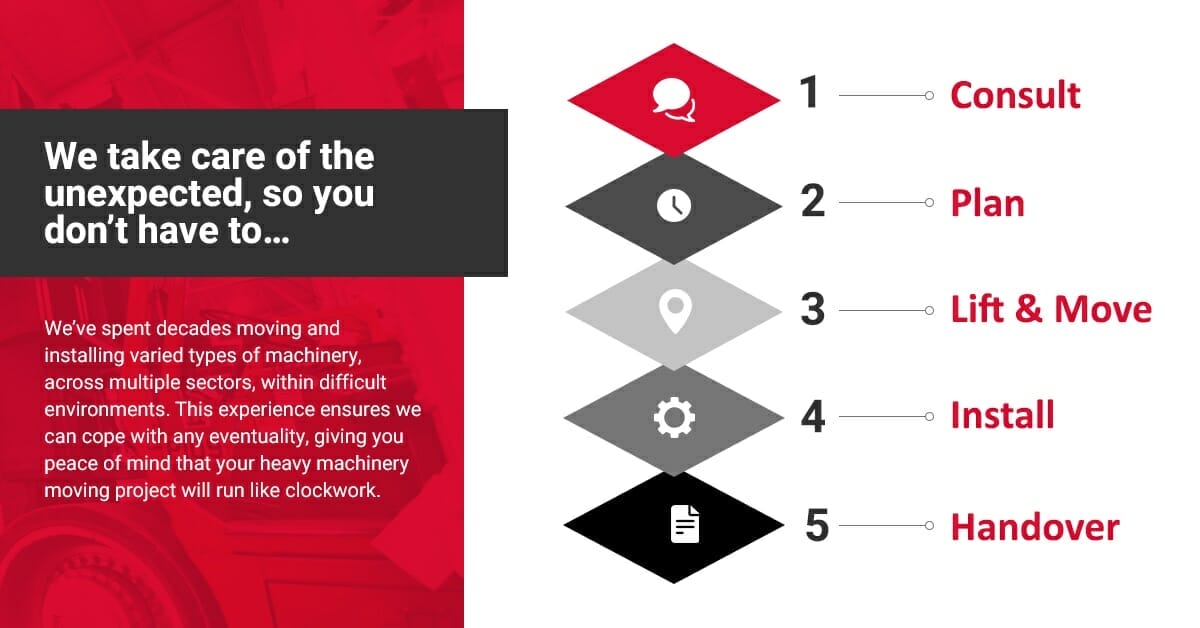

When it comes to factory relocation projects, we understand the potential risks involved, and as part of our process our management team will begin with an in-depth discussion to understand your factory relocation project.

A thorough site visit will then be carried out to assess the complexities of the project. During this phase, Merritts will liaise with site staff to discuss decommissioning works, timescales, traffic movements, access requirements, floor preparation and any other specific arrangements which may include working out of hours and weekend working.

Following the consultation, a cost and detailed plan for your project will be provided. Once the plan is agreed, all the necessary paperwork, including project plan, method statement, risk assessments and lifting plans will be presented prior to commencement of works.

At the core of our factory relocation service is a commitment to ensure works are completed in a safe, timely and cost-effective manner.

Our clients are high profile UK and international brands across a wide range of sectors which means we can also offer packing, import, and export services if the factory location involves overseas transportation of heavy machinery.

On all factory relocation projects, we work in partnership with you to understand your requirements to ensure the project meets budgets and deadlines. Our aim is to minimise production down time as much as possible.

Environmental Sustainability in Heavy Machinery Moving

Unravelling the Complexities Affecting the Cost of Heavy Machinery Moving

Tips for Minimising Downtime During Heavy Machinery Relocations

Merritts Heavy Machinery Moving Highlights of 2023

Factors to Consider When Carrying Out the Removal of Heavy Redundant Machinery

Optimising Factory Space: A Guide to Removing Redundant Heavy Machinery

Why Factory Relocation Services Are Key to Business Expansions

Machinery Moving experts take delivery of 4 Scania Tractor Units

In-Depth Look: The Factory Relocation Process with Merritts

How to Plan a Factory Relocation

Top manufacturing trends that will affect factory relocation in 2023

What vehicles and equipment does Merritts use to carry out factory relocations?

Our ongoing monitoring of industry sector trends means we can plan our continual investment in market-leading equipment, vehicles, and high-calibre personnel to ensure we have the necessary resources to safely carry meet the demand for a professional factory relocation machinery moving service.

Our fleet of lifting equipment includes:

- Pick and Carry Cranes

- Versa Lifts (Electric, and Gas Powered)

- Lorry Mounted Cranes

- Hydraulic Jacking Systems

- Forklift Trucks (Electric, and Gas Powered)

Our varied range of transport solutions includes:

- Low loaders

- Flat trailers

- 3 and 4 axle semi low loaders

- Lorry mounted crane options

- Curtain siders

- Step frames

What you can expect from our personnel:

Your project manager will be supported by a fully trained engineering team which comprises: SSSTS trained foremen, riggers, HGV Class 1 & 2 drivers, crane operators and electrical & mechanical engineering specialists. Merritts also employ fully certified slinger signallers, banksmen, and appointed persons to provide competent supervision when carrying out your factory relocation projects.

To help you plan a seamless factory relocation project we recommend following the below checklist.

Advanced Planning

When it comes to organising a factory move, it is always advisable to allow as much time as possible to appropriately plan each aspect of the project. These factors include the scope of the project, timelines, budgets, and resources required. This plan should include a detailed inventory of all equipment and machinery, as well as layout drawings of the new location to ensure that all equipment and machinery can be accommodated.

Factory relocations are especially popular during periods of inactivity or reduced production, such as Easter, Summer, Christmas, and other planned shutdown periods. It is therefore essential that planning begins well in advance of these periods.

Appoint An Experienced Plant Relocation Services Specialist

Moving machinery is an extremely specialised service, and it is imperative that you appoint a reputable heavy machinery moving specialist that has the in-house capability, experience, and knowledge to provide a comprehensive turnkey package.

The key factors that should be considered when evaluating your potential project partners are the following:

- Do they have skilled personnel with the necessary training accreditations to carry out the required work?

- Do they own the appropriate lifting plant to safely and efficiently complete the required machinery lifting and moving aspects, backed up with maintenance and inspection records for the plant?

- Do they have a- long-established history and reputation for carrying out factory relocation projects?

- Do they have an in-house qualified health and safety team that can design detailed risk assessments, method statements and lift plans, as well as being present on site to continuously monitor project safety?

- It is also important to observe customer reviews and testimonials to gain a better understanding of the machine mover’s credentials.

Consultation Process

Once you have appointed your heavy machinery moving specialist, an initial meeting should be held to discuss the requirements of the project. Site visits should then be carried out to assess the complexities of the project. During this phase, Merritts would liaise with site staff to discuss decommissioning works, timescales, traffic movements, access requirements, floor preparation and any other specific arrangements which may include working out of hours and weekend working.

Following the consultation, a cost and detailed plan for your project should be provided. Once the plan is agreed, all the necessary paperwork, including project plan, method statement, risk assessments and lifting plans should be presented prior to commencement of works.

A site-specific risk assessment could include:

- Reviewing floor conditions for load bearing integrity and identify any other possible issues such as uneven ground or the placement of any manhole covers and gutters etc. that may affect machinery moving.

- Arrangements for cordoning off the areas where the machinery is being transported or installed to ensure a safe working environment.

- Traffic restrictions and the need for traffic regulation orders if road transportation is required.

- The specific requirements for personal protection equipment (PPE)

- Consideration of any access restrictions such as doorways, ceiling heights etc.

- The requirement for operating out of standard working hours.

Upon completion of the install, there should be a final consultation with the customer to ensure all agreed aspects of the project have been delivered. The machinery should be inspected, and if satisfactory, the works should be signed off by the customer.

If you are considering a machinery removal to a new factory, factory relocation project, or installation project, need to temporarily store new or redundant heavy machinery, or simply need space to carry out servicing and maintenance, please get in touch.