Call FREE: 0800 046 9840

Email us: enquiries@merritts.uk.com

In terms of difficult challenges, a factory relocation project can often be a daunting prospect for companies to undertake. In most situations, a busy facilities manager will recruit an external heavy machinery moving specialist, who has the experience and understanding that for a successful factory relocation to occur, disruption and downtime must be kept to a minimum, as well as completed in a cost effective and timely manner.

Over 100 years of successfully completing factory relocation projects

As a result of over 100 years of experience, we understand the unique challenges that any production or assembly line changes, machine removals, or plant relocations required as part of a factory relocation project, can cause a major disruption to your manufacturing facility.

From disconnecting and dismantling plant in existing factories, to transporting them, reassembling and reconnecting them at a new site, our project management team will plan accordingly to ensure minimal production interruption during the relocation process.

We work closely with a customer base which ranges from local SMEs to global organisations in sectors such as aerospace, defence, automotive, food & drink, education, textiles, plastics, waste & recycling, metalwork, healthcare and pharmaceutical manufacturing.

What does Merritts factory relocation service look like?

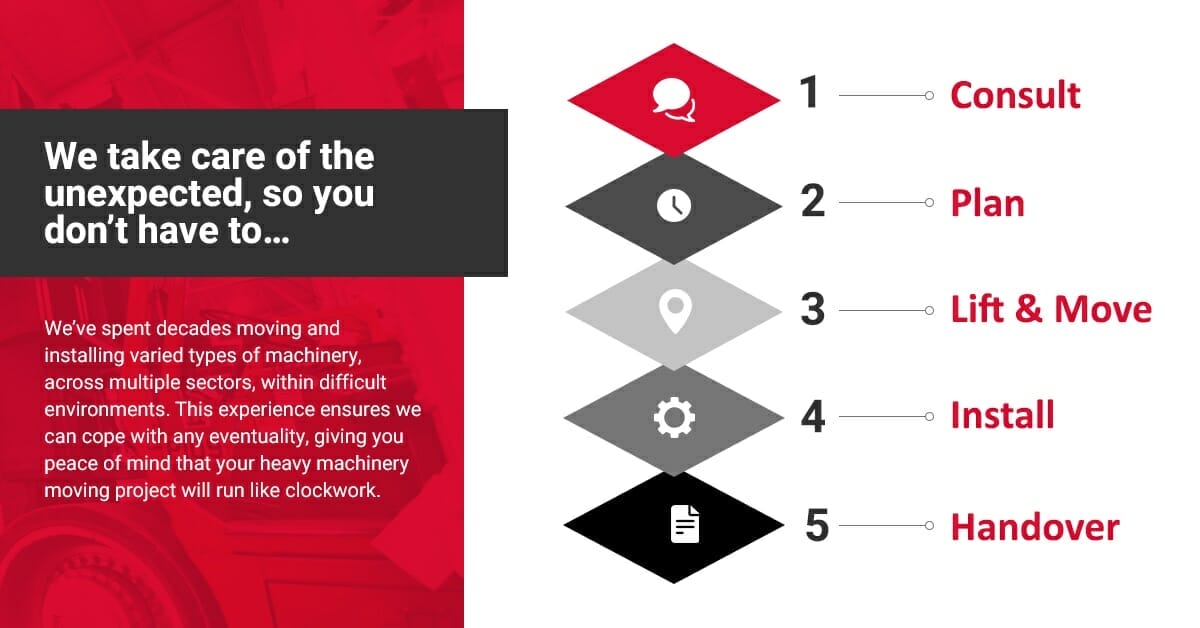

When it comes to factory relocation projects, we understand the potential risks involved, and as part of our process our management team will begin with an in-depth discussion to understand your factory relocation project.

A thorough site visit will then be carried out to assess the complexities of the project. During this phase, Merritts will liaise with site staff to discuss decommissioning works, timescales, traffic movements, access requirements, floor preparation and any other specific arrangements which may include working out of hours and weekend working.

Following the consultation, a cost and detailed plan for your project will be provided. Once the plan is agreed, all the necessary paperwork, including project plan, method statement, risk assessments and lifting plans will be presented prior to commencement of works.

At the core of our factory relocation service is a commitment to ensure works are completed in a safe, timely and cost-effective manner.

Our clients are high profile UK and international brands across a wide range of sectors which means we can also offer packing, import, and export services if the factory location involves overseas transportation of heavy machinery.

On all factory relocation projects, we work in partnership with you to understand your requirements to ensure the project meets budgets and deadlines. Our aim is to minimise production down time as much as possible.

What vehicles and equipment does Merritts use to carry out factory relocations?

Our ongoing monitoring of industry sector trends means we can plan our continual investment in market-leading equipment, vehicles, and high-calibre personnel to ensure we have the necessary resources to safely carry meet the demand for a professional factory relocation machinery moving service.

Our fleet of lifting equipment includes:

- Pick and Carry Cranes

- Versa Lifts (Electric, and Gas Powered)

- Lorry Mounted Cranes

- Hydraulic Jacking Systems

- Forklift Trucks (Electric, and Gas Powered)

Our varied range of transport solutions includes:

- Low loaders

- Flat trailers

- 3 and 4 axle semi low loaders

- Lorry mounted crane options

- Curtain siders

- Step frames

What you can expect from our personnel:

Your project manager will be supported by a fully trained engineering team which comprises: SSSTS trained foremen, riggers, HGV Class 1 & 2 drivers, crane operators and electrical & mechanical engineering specialists. Merritts also employ fully certified slinger signallers, banksmen, and appointed persons to provide competent supervision when carrying out your factory relocation projects.

Ensuring the highest levels of health & safety standards are met:

Our factory relocation process includes the following health & safety aspects:

A site-specific risk assessment:

- We review floor conditions for load bearing integrity and identify any other possible issues such as uneven ground or the placement of any manhole covers and gutters etc. that may affect machinery moving.

- Arrangements for cordoning off the areas where the machinery is being transported or installed to ensure a safe working environment.

- Traffic restrictions and the need for traffic regulation orders if road transportation is required.

- The specific requirements for personal protection equipment (PPE)

- Consideration of any access restrictions such as doorways, ceiling heights etc.

- The requirement for operating out of standard working hours.

Merritts provide a comprehensive health and safety pack that is submitted to all customers for approval before work commences. This means that if our customers have any queries and would like to amend anything, the necessary changes can be implemented.

This H&S pack includes detailed lifting plans to address the foreseeable risks involved in the work and to ensure that there is also a clear understanding of how lifting work is to be executed. We account for numerous factors when designing lift plans for our customer’s factory relocation projects. These include:

- Attaching/detaching and securing loads

- Weight distribution of the machinery/equipment that is being lifted

- Visibility

- Environment

- Pre-use checking

- Overload

- Location

- Proximity hazards

- Working under suspended loads

- Derating

- Overturning

- Continuing integrity of the equipment

A method statement is provided for all works, which comprehensively explains how works are to be carried out. We include SOP’s (safe operating procedures) for all machinery and equipment that is to be used in the factory relocation project, as well as providing a full suite of training records for our operatives, and inspection certification for any lifting plant that is being utilised.

All this information gives our customers confidence that their investments will be handled safely.

An integral part of our service includes Toolbox Talks. This is where we brief all site personnel prior to works commencing to ensure they fully understand the lifting plans, timescales, machinery movements and health and safety requirements for the project including PPE specification. All Merritts staff wear branded uniforms and hi-vis clothing so that they are instantly recognisable when working on site and represent our customers in a professional manner.

Owing to our attention to detail, knowledge of health and safety issues, ongoing staff training program and the regular maintenance of transportation and lifting equipment, we are very proud of our health and safety record when carrying out factory relocation projects.

Case Study – Dismantling, Removal and Relocation of manufacturing machinery to a new facility

TW Ward CNC Machinery Ltd’s client, Ekspan Ltd, required a number of machines to be removed from their existing premises in Sheffield, and relocated to their new facility in Tankersley, Barnsley, 10 miles away. Works were completed over a 3-day period.

Overview of services provided;

- Provision of all required health and safety documentation, including risk assessments, method statements and bespoke lift plans.

- Where required, dismantling of machinery at the existing site was carried out to facilitate loading and transportation to the new facility.

- The supply of heavy lifting plant which included our 58Te capacity pick & carry crane and Versa-Lift 60/80 with 36Te lifting capacity, both with remote controlled functionality.

- Sheeting of machinery prior to transit to ensure protection along the route.

- The provision of specialist trailers, including ‘wafer deck’ trailers to ensure the safe transport of tall loads.

- Delivery of machinery to the new facility including the arrangement of ‘movement orders’ for the ‘out of gauge’ loads.

- Offloading of machinery into the new facility plus rebuilding and final positioning.

- Provision of ‘all risks’ insurance cover for the project duration.

To view the full case study, click here

If you are considering a machinery removal to a new factory, factory relocation project, or installation project, need to temporarily store new or redundant heavy machinery, or simply need space to carry out servicing and maintenance, please get in touch.