Whilst some will be looking forward to a well-deserved break during the Easter shutdown period, a busy production manager will be tasked with coordinating the installation of new machinery, the improvement of operational efficiencies or perhaps even a factory relocation project.

Plant machine moves

Out of Hours Solutions for Heavy Machinery Moving Projects

Merritts regularly operate heavy machinery moving projects out of standard working hours and can also accommodate night and shift working as well as weekends for moves that are time and/or production sensitive.

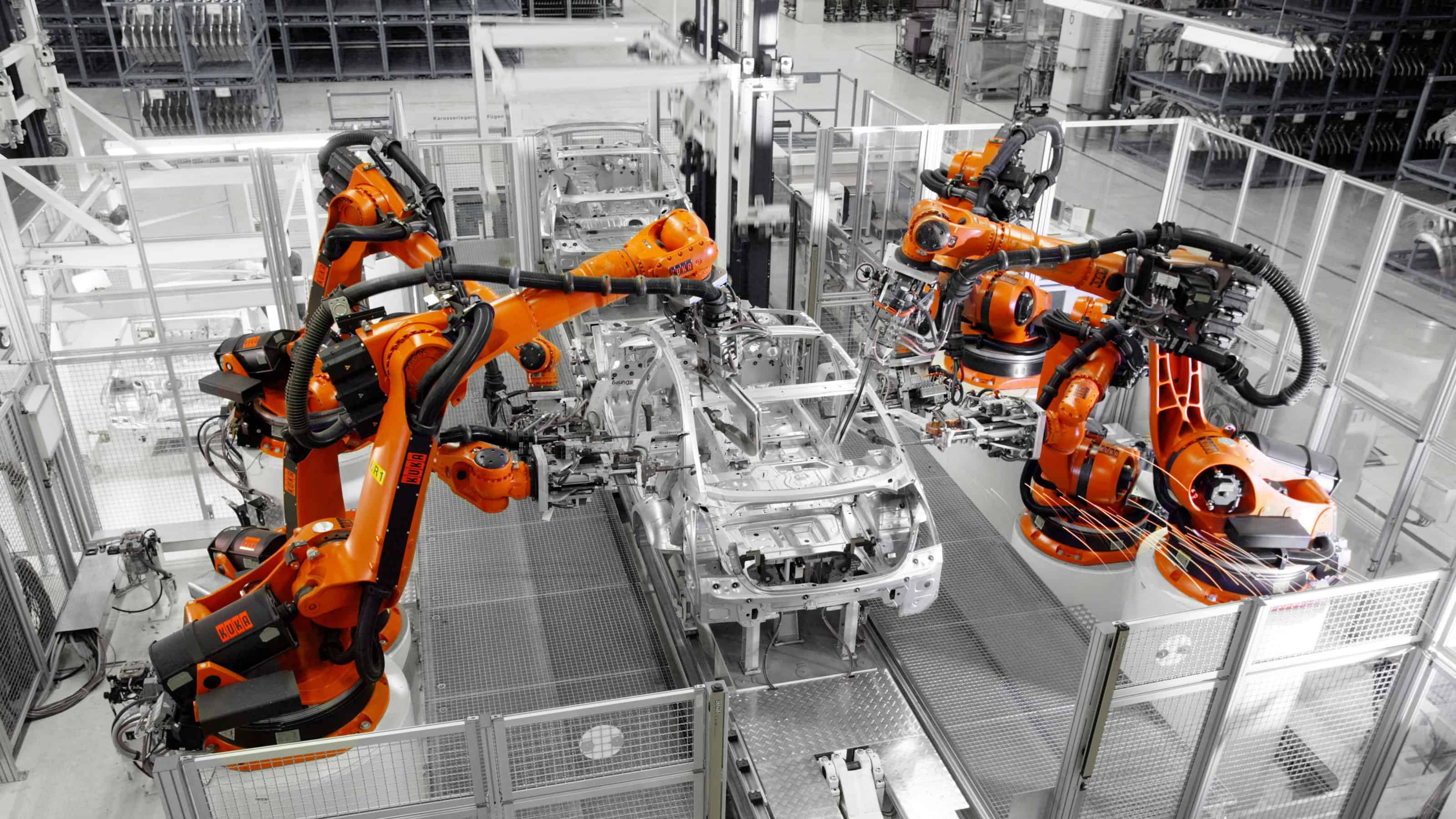

Heavy machinery moving for automotive plant de-commissioning

If you have been appointed with the task of de-commissioning a car assembly line and need heavy machinery removed and transported to a new location, Merritts can help. We specialise in heavy machinery moving for automotive plant de-commissioning and have highly skilled project managers who will ensure everything runs smoothly.

Health and safety regulations that influence a heavy machinery moving project

Our article outlines the important health and safety technical details for anyone considering a heavy machinery moving project.

PUWER regulations and how they relate to heavy machinery moving

The purpose of the PUWER regulations is to ensure that those using and working with equipment and machinery, such as employees, employers, contractors, traders and anybody who could possibly have access to equipment or machinery in a workplace, does so in a safe working environment.

Merritts Owner and Managing Director gives his 2019 business predictions

East Midlands Business Link Magazine recently sat down with our Owner and Managing Director, James Merritt to get his 2019 business predictions.

Top tips for planning a heavy machinery moving project

If you’re planning a heavy machinery moving project, here are some top tips that may help you meet deadlines and budgets in a safe and cost effective manner.

Health & Safety Guide to Moving Heavy Machinery

Moving heavy machinery? This is our health and safety guide to help you move your machinery smoothly, on time, to budget and without injury or incident!

Heavy Machinery Refurbishment Space

Merritts has 60,000 ft² of internal warehouse space serviced by overhead cranes, and a further 80,000 ft² of external storage space. This enables us to offer manufacturing businesses and machine tool specialists the opportunity to use our facilities as a base from which to carry out heavy machinery refurbishment and maintenance.

Merritts Appoint New Contracts Manager

Merritts Machinery Movers are pleased to announce the appointment of Russell Taylor as the companies’ new Contracts Manager.

Merritts Machine Movers Invest in New Vehicles

Merritts Machine Movers recently completed the purchase of two brand new Mercedes Benz Actros 2651 Gigaspace tractor units to add to the companies current fleet of specialist vehicles.

Industrial Storage | Keeping your assets safe and sound

As part of Merritt’s bespoke services we provide safe and secure Industrial storage services for large loads and industrial equipment. This is often essential when equipment is being mothballed, sold on or can’t be transported to its final destination for a period of time.