Call FREE: 0800 046 9840

Email us: enquiries@merritts.uk.com

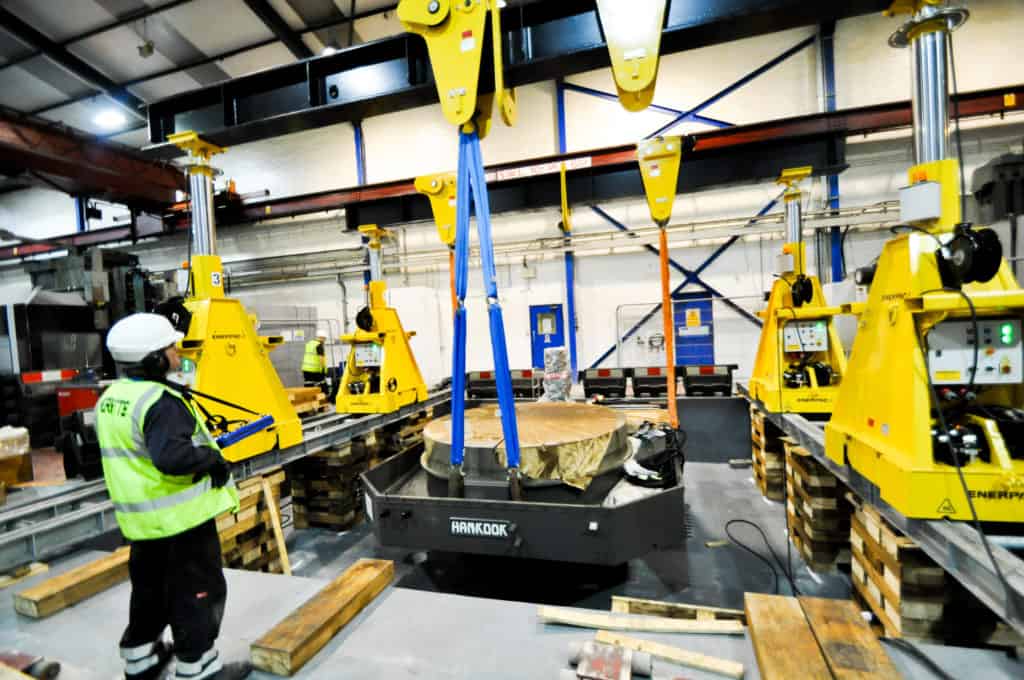

Merritts work across multiple sectors, regularly carrying out over 100 heavy machinery removal, installation, and transportation projects per month. We provide the world’s leading machinery manufacturers with specialist machinery moving, lifting, installation and storage services.

A major aspect of the service we provide is our commitment to health and safety. For each project, our H&S Department, headed by an ex HSE inspector, provides customers with a suite of documents to evidence our credentials. These include method statements, risk assessments, lift plans, personnel training records and plant and equipment inspection certificates. This helps to ensure all projects will be carried out safely and in accordance with the required legislation.

The examples below highlight just a few of the heavy machinery moving projects that we completed last month.

Removal of Evaporator Line & Factory Consolidation for the Automotive Sector

The relocation scope for this project included mains services disconnection, mechanical dis-assembly, lifting, movement and transport of machinery including wide and heavy loads, offloading, installation in Europe, reconnection and recommissioning including fabrication and site modifications to equipment.

Machinery involved vacuum brazing furnaces, power presses, chemical etching & wash plant, injection moulding machinery, metal working machinery and helium testing lines.

Mains electrical, pipework, and material feed system were installed under work packages that were subcontracted and managed under CDM.

Merritts were responsible for the decommissioning and recommissioning of machinery and robot feed systems. This included the engagement and management of specialist OEMs and robot technicians working to the project plan.

Installation of Machinery for the Healthcare Sector

Merritts were appointed to carry out the offloading, unpacking and installation of production machinery for a Swindon based medical device manufacturing company. Due to the sensitive environment, Merritts used their electric forklift trucks to safely transport and position the equipment within the facility.

Completion of a 6 Month Project Consolidating Machinery From Four Sites into Two

This project was carried out for a company who specialise in engineering polymer solutions. Machinery was removed from 4 sites and consolidated into 2. Machinery consisted of CNC machines, furnaces, ovens, and shot-blasting machinery.

A project manager was on site throughout the whole project, liaising with the customer and personnel to ensure the project remained on track at all times.

A health and safety manager was also at hand to identify any potential risks and to maintain safe working conditions through to project completion.

Offload and Position Packaging Machinery for the Food & Drink Sector

This project consisted of Merritts offloading crated machinery from transport. The machinery in question was a full packaging automation line for a food manufacturing company in Burton on Trent. Equipment was de-crated, transported into the customer’s facility and assembled under the supervision of the equipment manufacturers.

Relocation of an Atmospheric Chamber On-Site at Lincoln

Works involved:

- Electrical and mechanical disconnection of the chamber

- Lifting and removal of the chamber from the current facility

- Loading to trailer and transporting to new location on the existing site

- Offloading and siting of the chamber at the new location

- Machinery assembly, reconnection and levelling was then carried out

These works were carried out for a major designer and manufacturer of PLM software.

If you are considering a heavy machinery removal, relocation or installation project, need to temporarily store new or redundant heavy machinery, or simply need space to carry out servicing and maintenance, please get in touch.

We’ll be back next month with another update, but until then you can follow us on LinkedIn and Twitter for more regular news from our team.