Call FREE: 0800 046 9840

Email us: enquiries@merritts.uk.com

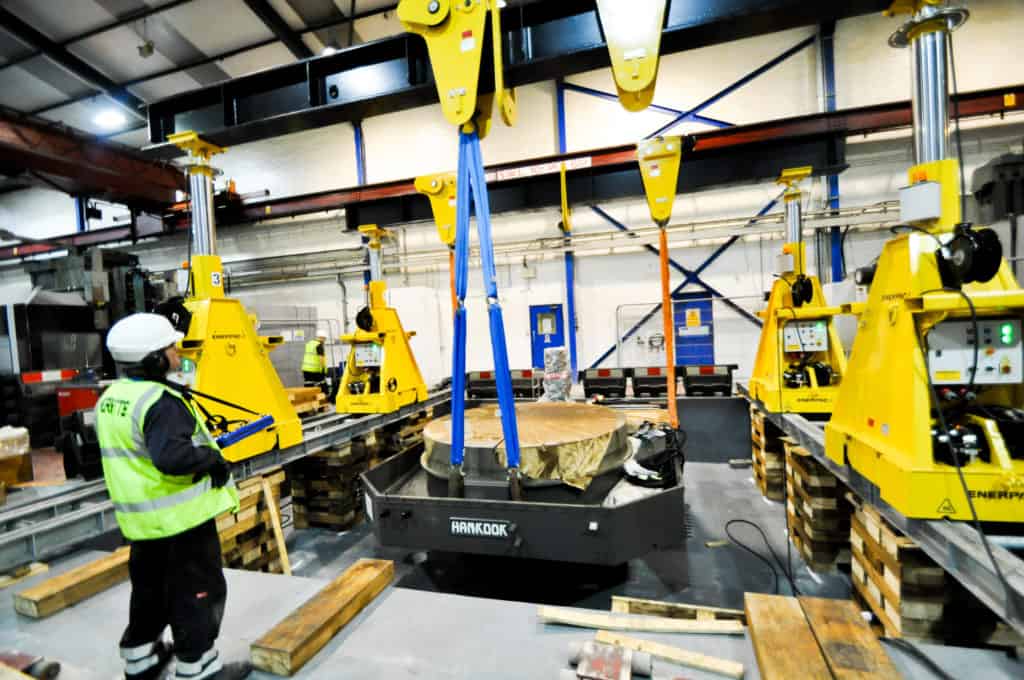

Merritts were tasked with carrying out the transport, offloading, movement and installation of a Hankook Vertical Turning Centre for customer Ward CNC, at their customers site in Lancashire. The 3 main sections of the machine consisted of: 32Te base, 22Te column and a15Te cross rail section.

Challenges

- Space Restriction: Due to surrounding machines still being operated within the facility, moving them was not an option. This left little room for manoeuvre.

- Time Scales: Each phase of the works had to be completed within a specific time frame to ensure ongoing works within the factory were not disrupted.

- Below Ground: The lathe had to be precisely positioned within a pit, 1.2m below ground level

Merritts built up the Super Lift gantry on the day prior to works commencing, in order to maximise the amount of time for the following day. This would ensure we remained within the scheduled time frames.

The machine pit was constructed, painted and floor holes were drilled to accept the base of the machine.

The VTC base section was collected from Ward CNC and delivered to site via Merritts transport. The 32Te piece was offloaded with Merritts’ Versa-Lift 60/80. The 60/80 is capable of lifting & carrying up to 36Te in a single move.

One end of the base was placed onto skates, the other was held by the 60/80. The machine was then moved into the facility.

The remote controlled functionality of the Versa-Lift 60/80 is particularly useful when space is tight, as it allows the operative to move around the machine, whilst simultaneously guiding it along, ensuring there is no contact with any of the surrounding machinery.

The base was placed in front of the pit. The base was lifted by the Superlift gantry and lowered into the machine pit.

The 22Te column section was tandem lifted from transport by the Versa-Lift 40/60 and the Versa-Lift 60/80. The column was placed onto machinery moving skates and move into the facility.

Once inside, the Versa-Lifts again worked together to orientate the column into an upright position and place it in front of the machine pit. The Superlift gantry was then used to move the column onto the base section within the pit. The column was secured in place by OEM engineers.

The 15Te Crossrail section was offloaded from transport with the Versa-Lift 60/80 and carried directly into the facility. The Crossrail was lifted by the Superlift gantry and moved up to the face of the column section. OEM engineers then proceeded to bolt the Crossrail securely to the column.

Merritts completed the final elements of their works before handing over to the OEM engineers for final commissioning.

Equipment Used

- Enerpac Super Lift (SL125) gantry

- Versa-Lift 60/80 (remote controlled)

- Versa-Lift 40/60

- 7Te FLT

- Cherry Picker

- Rigging tackle

- 10Te overhead crane