Call FREE: 0800 046 9840

Email us: enquiries@merritts.uk.com

The relocation of injection moulding machinery from a production facility in Dubai to a new location in the UK

Company Profile: Polypipe are the UK market leader in the design, development and manufacture of thermoplastic piping systems for civil and infrastructure projects. The company provides water management, surface water drainage, sewer and cable protection systems.

Project Outline: Merritts were engaged by Polypipe Civils to decommission and relocate 4 ENGEL injection moulding machines over a 3 week period from their plant in Dubai, UAE, to their production facility in Horncastle, UK where they were installed and recommissioned.

Planning Phase:

- Merritts project managers carried out a site visit in Jebel Ali, Dubai, to fully understand the requirements involved and to create a detailed scope of works for the project.

- When the scope of works were finalised; method statements, risk assessments and lifting diagrams were issued to the customer for approval.

- Once the RAMS and lifting methods had been approved, Merritts arranged for their mechanical, electrical and rigging personnel to fly out to Dubai.

- UAE temporary permits to work were obtained for all members of staff involved in the project.

On Site, Dubai:

- Merritts ensured machinery was disconnected from mains services and oils were drained.

- Moving parts on the machinery were locked off with OEM transit brackets.

- Merritts used the facility’s overhead crane to lift the Viper robots from the machinery and place onto bearers within pre-manufactured timber cases. This process was also used for the machinery’s tie bar pullers.

- Merritts mechanical and electrical engineers then separated the clamp and injection units on each machine.

- The clamp and injection units were then skated to an outside position and craned from a specially designed level steel platform and lowered onto pre-manufactured steel and timber packing bases.

Dismantling and loading

- The items were fully vacuum packed in foil bags and cases formed around them.

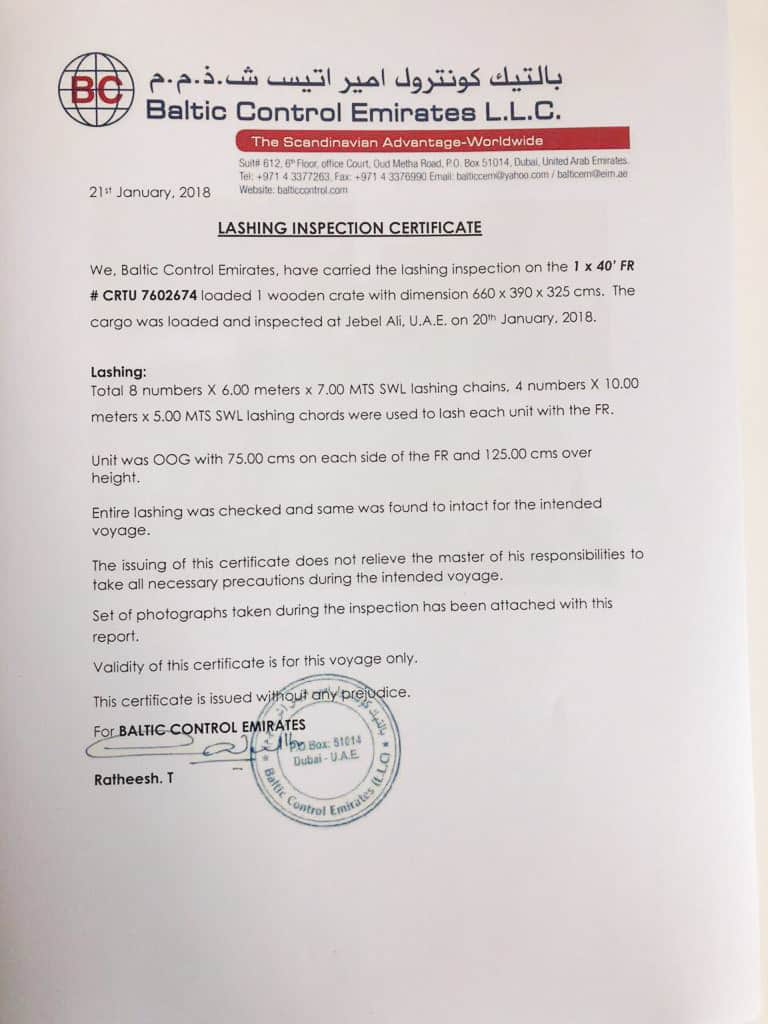

- Cases were loaded to flat racks and lashing inspection certificates received.

- The cargo was shipped ex Jebel Ali, Dubai, to Felixstowe, UK.

Transport

- Merritts arranged customs clearance of goods and collected all OOG cases from Felixstowe and delivered to Horncastle (all standard shipping containers delivered by the shipping line).

- Merritts erected the Enerpac Superlift gantry on site to offload all OOG machinery.

- All items were offloaded and unpacked to allow positioning, as instructed by the client.

- Machinery was skated into position with assistance from the Versa-Lift.

- Merritts mechanical and electrical engineers reassembled and reconnected the machinery.

- Peripheral equipment, including the Viper robots, was positioned using the on site overhead crane.

- When all machinery had been rebuilt and reconnected, the ENGEL engineer recommissioned the machinery.

Equipment Used

Dubai

- 200Te mobile crane

- 10Te FLT

- 7Te FLT

- MEWP

- Exported Merritts own rigging and lifting equipment

UK

- SL 125 Super-Lift Gantry

- Versa-Lift 60/80

- 2 x 7Te FLT’s

- MEWP

- 2 x Tackle Vans

- 2 Engel Duo 1000’s (57 Te per machine)

- 2 Engel Duo 350’s (37 Te per machine) + Viper Robots and peripheral equipment

Personnel

Dubai:

1 ENGEL Engineer

4 Mechanical Engineers

2 Electrician Engineer

2 Lead Riggers

UK:

4 HGV Drivers

1 ENGEL Engineer

4 Mechanical Engineers

2 Electrician Engineer

2 Lead Riggers

Projects like this exemplify the expertise we have in transporting heavy machinery regardless of the location or complexity. Due to the varied requirements of the project, I am very proud of the high-quality service delivered to the client by our project managers, health & safety team and on site operatives.